Hermetic feed-through terminals (glass sealed)

The processing temperature for glass encapsulation is 800-1000°C. Borosilicate and aluminosilicate glasses with low coefficients of thermal expansion are used.

In a typical heat treatment of 800-1000°C, encapsulating glass is used for hermetic sealing and electrical insulation between different materials such as metals, ceramics, or glass. SCHOTT's diverse line of standard and custom encapsulating glasses are available for a variety of coefficient of thermal expansion (CTE) materials. SCHOTT can provide glass matched to the coefficient of thermal expansion of the material to be encapsulated. SCHOTT encapsulating glass is available as powder or sintered preforms.

Glass Hermetic Seals

What is the purpose of glass encapsulation?

Glass sealing is a method of joining insulators and metals in vacuum applications. Glass sealing is a technique used to maintain an airtight seal between a special hermetically sealed environment and the outside environment by sealing with glass through a conductive metal pin, such as a signal line. Kovar glass and Kovar metal (alloy Fe : Ni : Co = 54 : 29 : 17) are fused together by heating. This method utilizes the similar coefficient of thermal expansion of the base materials, but its disadvantage is that it is vulnerable to external forces (impact, shrinkage, etc.). However, the disadvantage of this method is that it is vulnerable to external forces (impact, shrinkage, etc.).

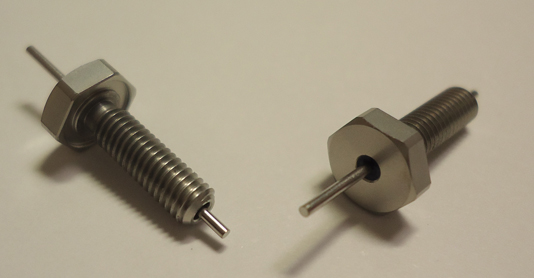

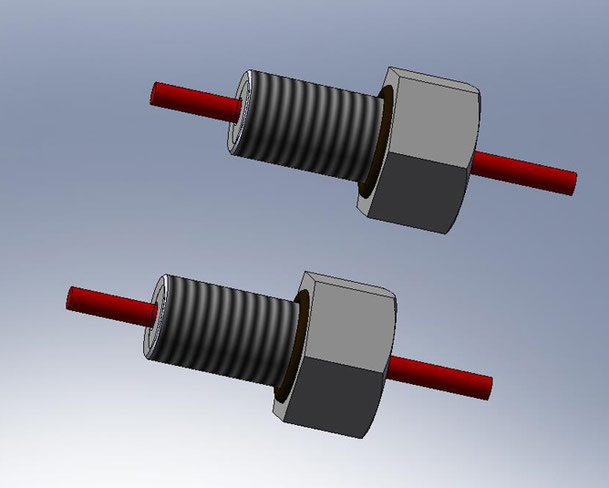

Hermetic (current-conducting) terminals

Hermetic equipment is required for work in vacuum, pressure, liquid, and gas environments.

Hermetic feed-through terminals are required to introduce power and extract various data signals inside hermetically sealed equipment without damaging the hermeticity of the equipment. Hermetic feed-through terminals provide quicker, easier, and more reliable hermetic continuity than other hermetically sealed connectors by providing standardized threaded holes in the hermetically sealed equipment housing.

Hermetic feed-through terminals are not connected with connectors, but with screw terminals and are called current-intake terminals or sealed terminals. Please select the size appropriate for your application.

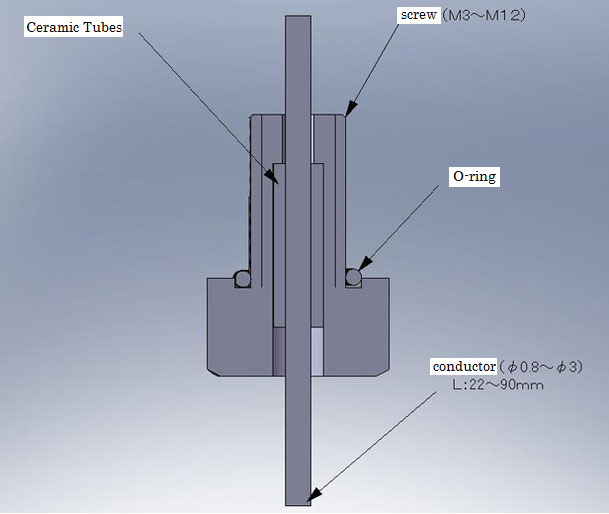

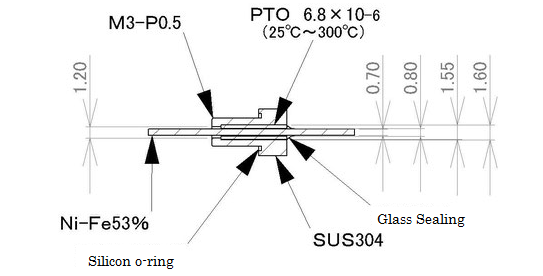

cross-sectional structure

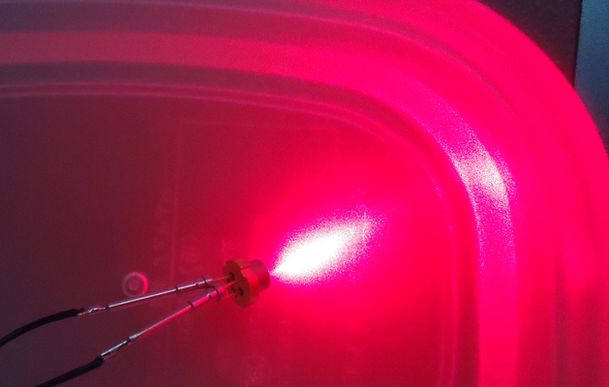

Our hermetic feed-through (current-conducting) terminals were developed and commercialized in response to the technological shift from the conventional complicated Peltier/water-cooled circulating heat dissipation system to a simple, corrosion-oxidation-free circulating heat dissipation system using fluorinert liquid, in order to dissipate heat from the element and obtain stable optical output, as the output of semiconductor lasers (LD) becomes higher. This is a new product developed and commercialized in response to the shift in technology from the conventional complex Peltier/water-cooled circulating heat dissipation method to a simple circulating heat dissipation method using a Florinert fluid that eliminates corrosion oxidation. The hermetically sealed through-hole terminal has enabled the creation of highly reliable, long-life, simple, high-power LD modules and the realization of technology that supports the stable drive of high-power LD modules.

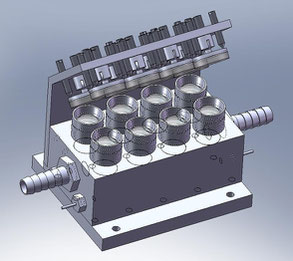

High power LD module with hermetic feed-through terminals

High power LD module with hermetic feed-through terminals

A semiconductor high-output LD device is placed in a Fluorinert solution,

However, the high-power LD device oscillated stably due to heat dissipation from the Fluorinert solution.

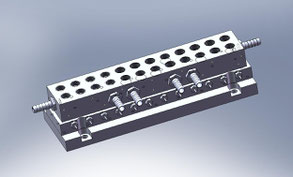

In the following module, a circuit board is placed to drive the semiconductor laser, while a large number of hermetic terminals are used to transmit the LD drive current into a sealed enclosure in which a Fluorinert solution is circulated to remove heat emitted from the LD element, and because the installation process is simple, hermetic terminals are used to achieve miniaturization.

Φ9CAN type high output LD module (24cH).

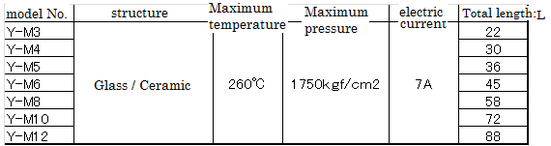

Hermetic feed-through terminal standard

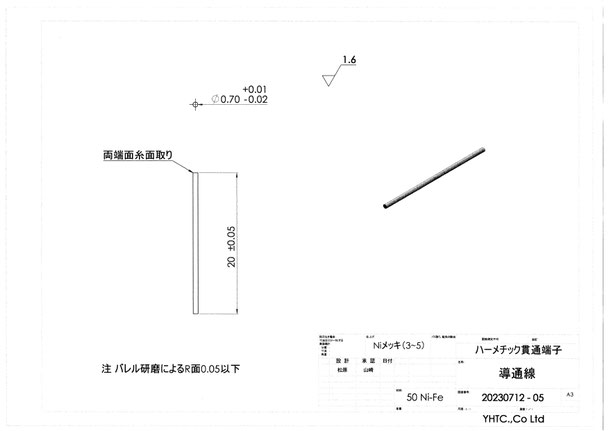

Conductive terminal: 50% Ni/Fe

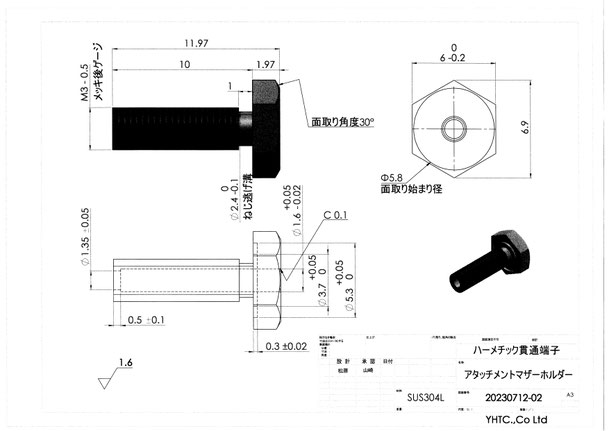

Threaded housing: SUS

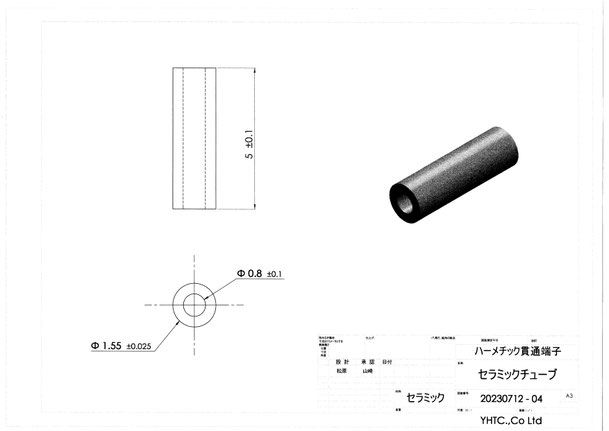

Insulating tube: Ceramic

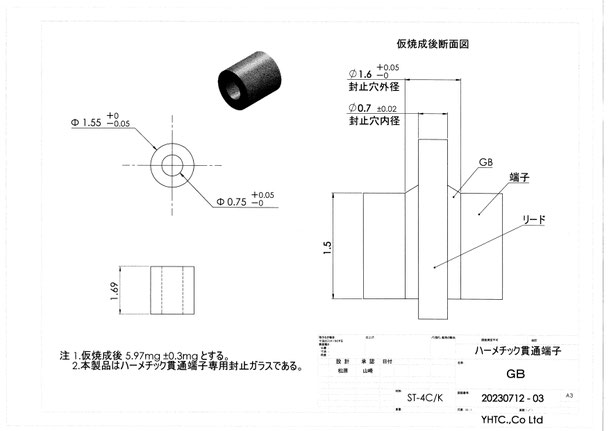

Encapsulant: Glass paste

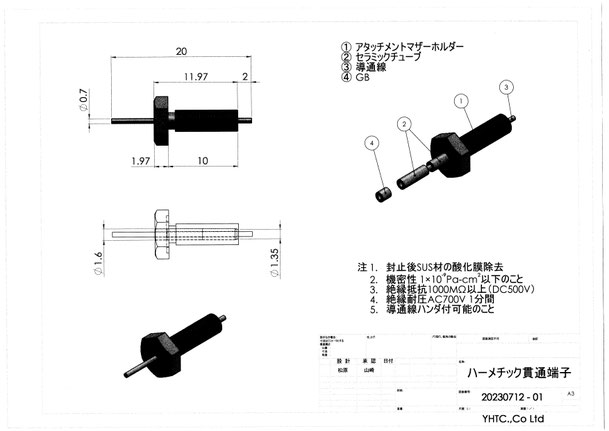

Hermetic (current-conducting) terminals (Y-M3)

The above figure shows the structure and dimensions of hermetic feed-through terminal Y-M3. Overall length: 22mm

We can manufacture hermetically sealed terminals that are unique to your company.

We can manufacture feed-through terminals other than those listed in the table above to meet your requirements. Please feel free to contact us.

We can develop prototypes of hermetic terminals that are unique to your company. Please send us your punch drawing and we will make a drawing to help you realize a useful component.

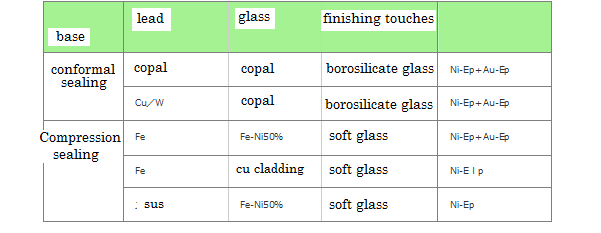

Selection of a combination that matches the expansion rate of the metal sealing material

We manufacture and develop various types of sealing terminals. We are particularly strong in metal and glass sealing technology, which has earned us trust and a proven track record. Our products are made by welding glass to metal in a high-temperature electric atmosphere furnace, and have excellent hermeticity, insulation, and heat resistance, making them suitable for a wide range of applications. We can also provide glass hermetics using aluminum. (Combination of Al-SUS, Al-Cu, Al-Ni, Al-Al alloys, etc.)

It is now applicable to lithium batteries and various other lightweight applications.

We provide unique hermetic terminals.

For safe and secure manufacturing, contact us

Below is a detailed reference drawing of a hermetic feed-through terminal

YHTC Co.,Ltd

半導体レーザ /半導体サーモ・モジュール制御要素部材

半導体製造設備ラインの延命保守サービス

|レーザドライバー|ペルチェドライバー|サーモモジュール|

|ヒートシンク|半導体レーザソケット|温度センサー|

|LDパイプソケット|レーザマウンター|卓上恒温槽|

|半導体レーザ/光送受信(O/E.E/O.変調)実験システム|

YHTC Co.,Ltd

半導体レーザ /半導体サーモ・モジュール制御要素部材

半導体製造設備ラインの延命保守サービス

|レーザドライバー|ペルチェドライバー|サーモモジュール|

|ヒートシンク|半導体レーザソケット|温度センサー|

|LDパイプソケット|レーザマウンター|卓上恒温槽|

|半導体レーザ/光送受信(O/E.E/O.変調)実験システム|